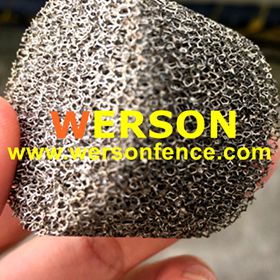

Nickel Iron Foam

Nickel Iron Foam has good high temperature and corrosion resistance, unique three-dimensional through-hole structure, uniform pores, and high strength. It is widely used in filtration of various harsh environments and the gas-fired panel installation of infrared burners. Its excellent processing performance, flexible shear cut.

Feature:

1. Ultra-lightweight: With the largest specific surface area, the specific gravity is 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, 1/30 of iron, ultra-light weight.

2. Sound absorption: porous structure has a wide frequency of sound absorption characteristics.

3. Electronic wave shielding: Through relatively thin thickness, about 90dB electronic wave shielding.

4. Processing performance: can cut, bent, and simply paste.

5. Fire resistance: to maintain a stable shape, it is difficult to burn at high temperatures, high temperature.

6. Recycling: Metal waste materials can be recycled 100%.

7. Heat conduction: porous material has a strong thermal conductivity.

8. Breathable: homogeneous three-dimensional network structure, a filtering effect, gas, fluid flow stability is super.

9. Sound Insulation: Through additional processing, a high noise interception can be obtained and the sound insulation effect is good.

10. Exquisite appearance, internal practical: through a variety of processing, suitable for interior decoration.

11. High temperature above 1100 degrees, resistant to a variety of acid and alkali corrosion, good permeability, uniform pore structure, heat and heat transfer faster.

The regular specification:

Thickness: 2mm

Aperture: 40PPI (0.1-10mm)

Porosity: 60-98%

Through hole ratio: ≥98

Bulk density: 0.1-0.8g/cm3

PPi (number of holes per inch length): 5-130

Maximum geometry: 600 × 600mm (can also be ordered upon request)

Tensile strength: 8-50MPa

Compressive strength: ≥250KPa (compressed to 50% pressure value)

Mechanical strength: 2-7MPa High temperature: >300°C Heat transfer coefficient: >3w/(m2k).

Application:

Exhaust gas purifier carrier materials, battery electrode materials, various catalyst carriers, especially for filter materials that require high temperature and acid and alkali corrosion resistance, surface layer materials for infrared burners, heating materials for various industrial and civilian drying equipment.

If you need to consult the price, please contact the business department by e-mail:

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.